physical prototyping

form: wearable prototype

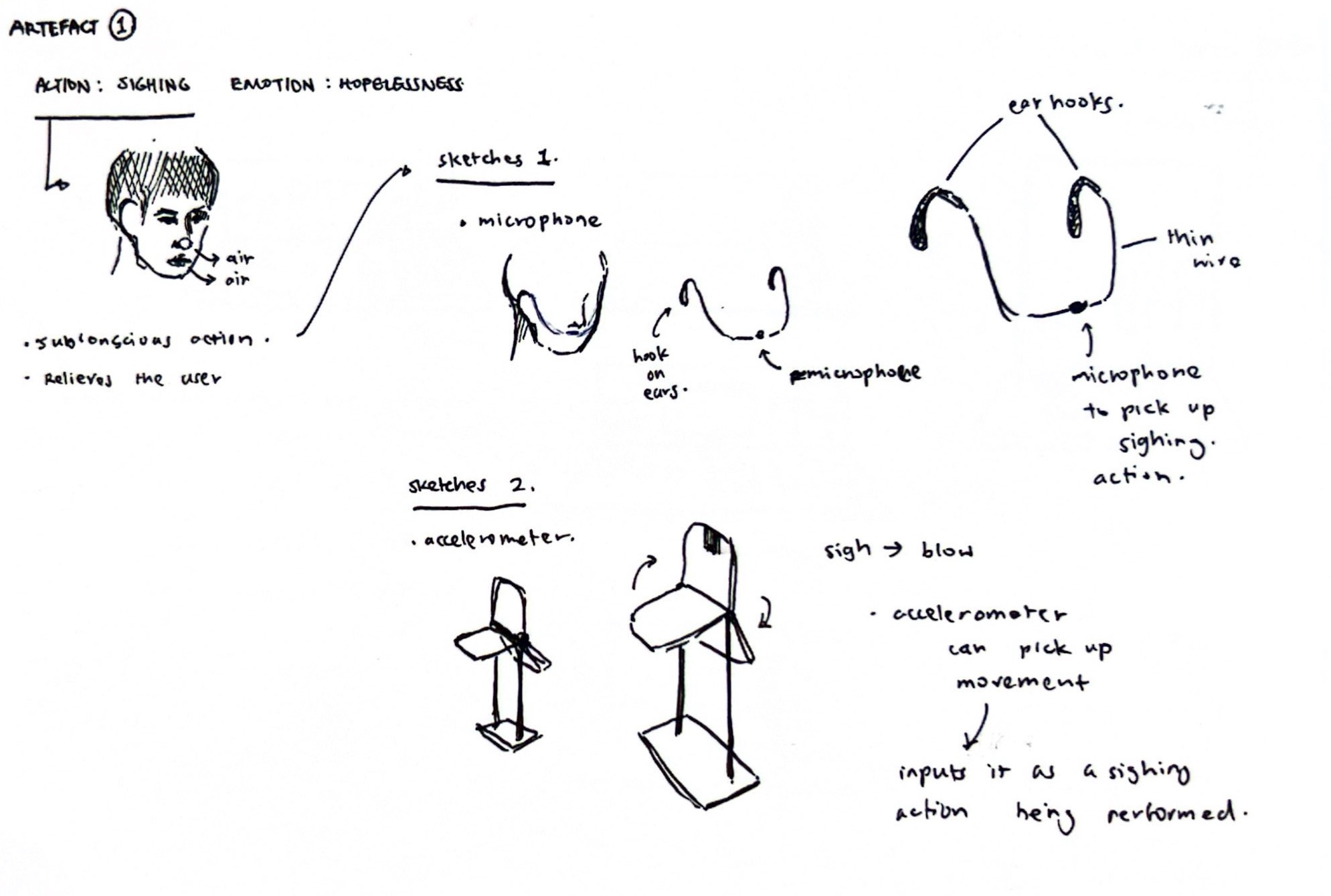

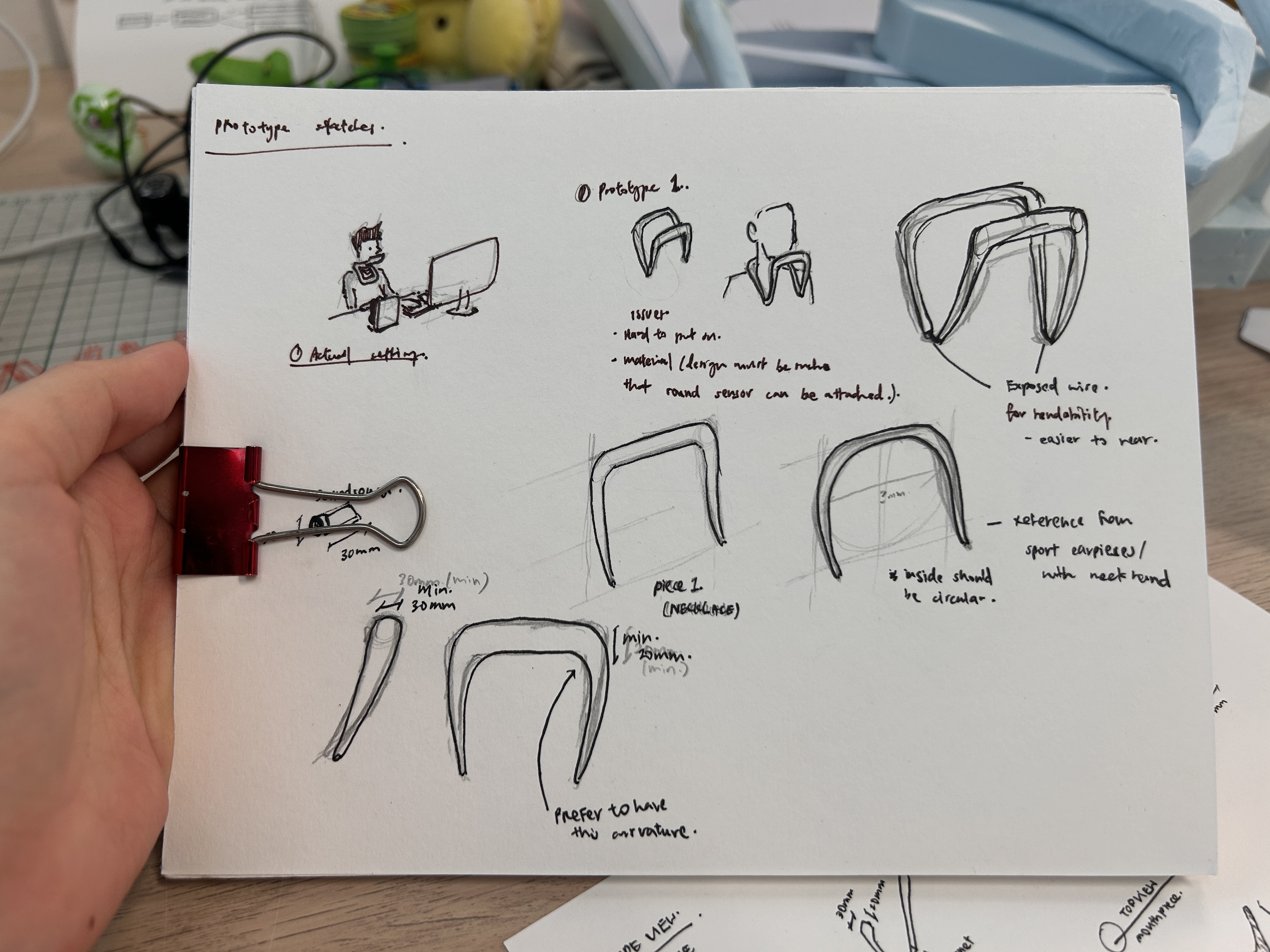

prototype-frustration 4.1: prototype-hopelessness: ideation of different approaches.

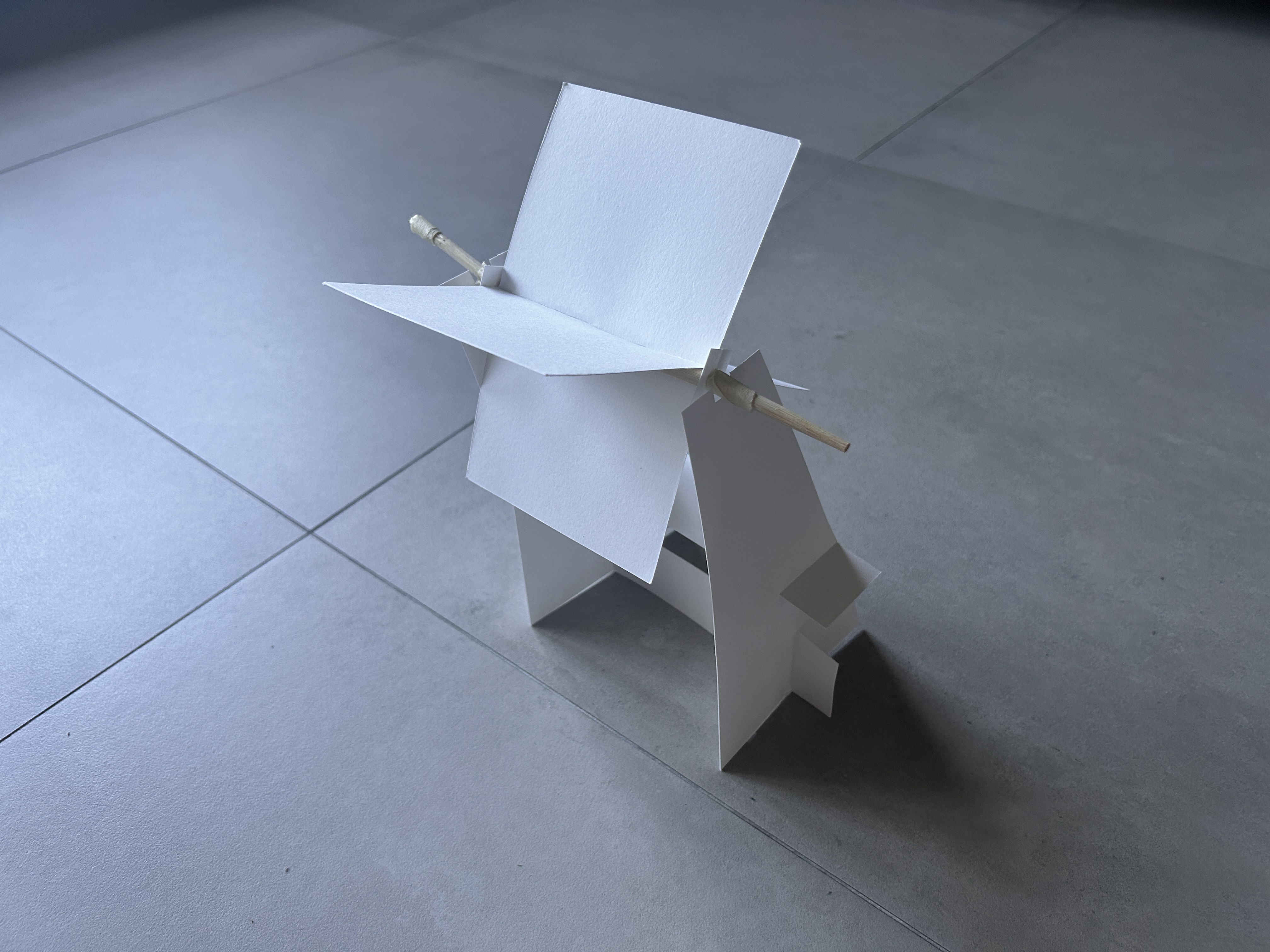

prototype-hopelessness 4.2: testing out different skeletal structures.

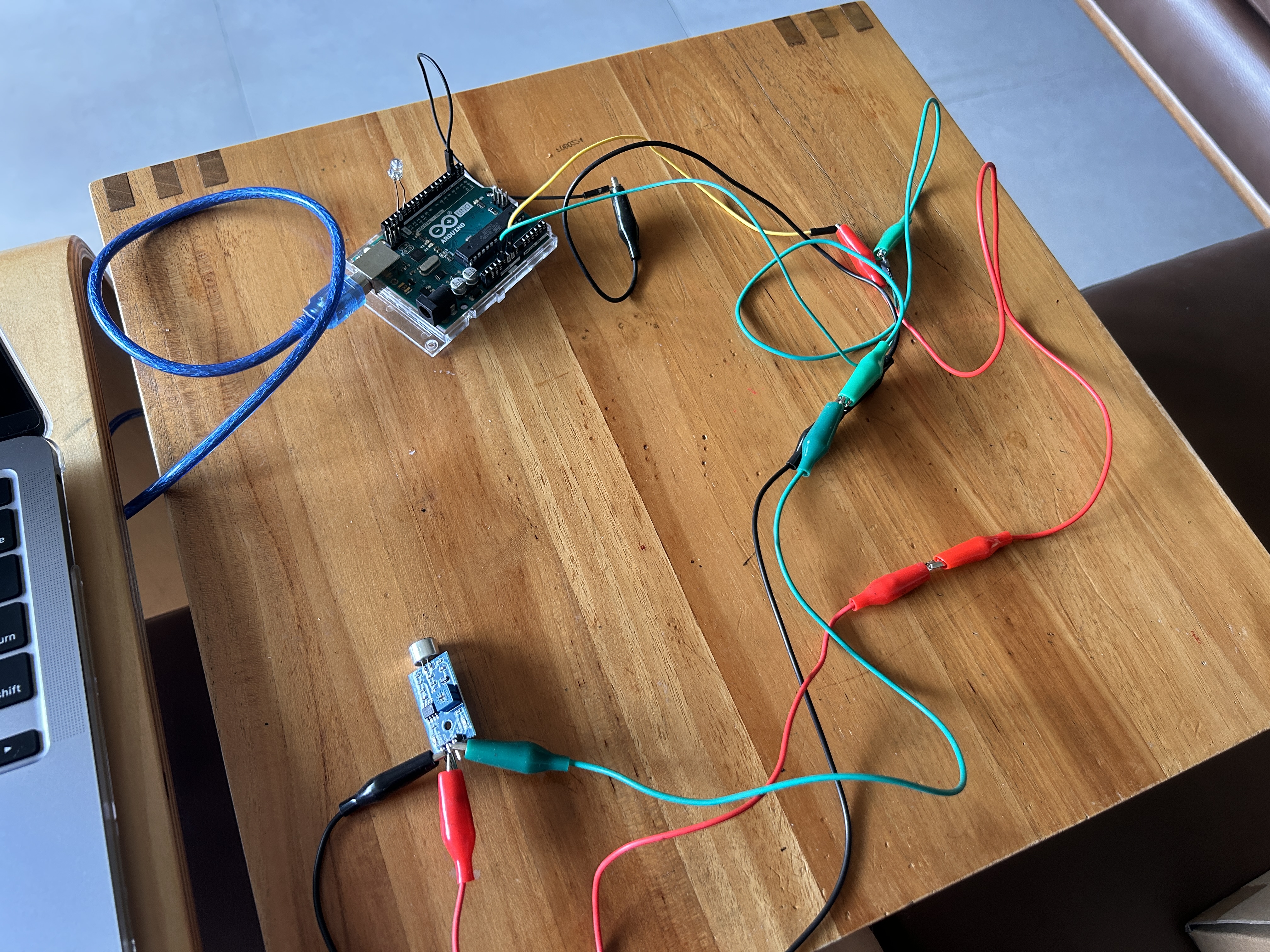

prototyping a basic system. date of completion unsure.

tests on different forms

i came up with two different approaches for the prototype: hopelessness. the wired one was to be worn, and would be able to pick up the most subconscious expressions. the windmill required the user to be more proactive and required a bit of sound monitoring. there are issues with both- the wired one would pick up unwanted noises as well, and the windmill might not be the most accurate in the collecting of data, and strayed a little further away from the original concept of monitoring subconscious actions.

after some feedback and thinking, i will proceed on with the wearable prototype. it is a bit closer to what i wanted of collecting subconscious actions.

prototype-hopelessness 4.2: iterations of the wearable prototype.

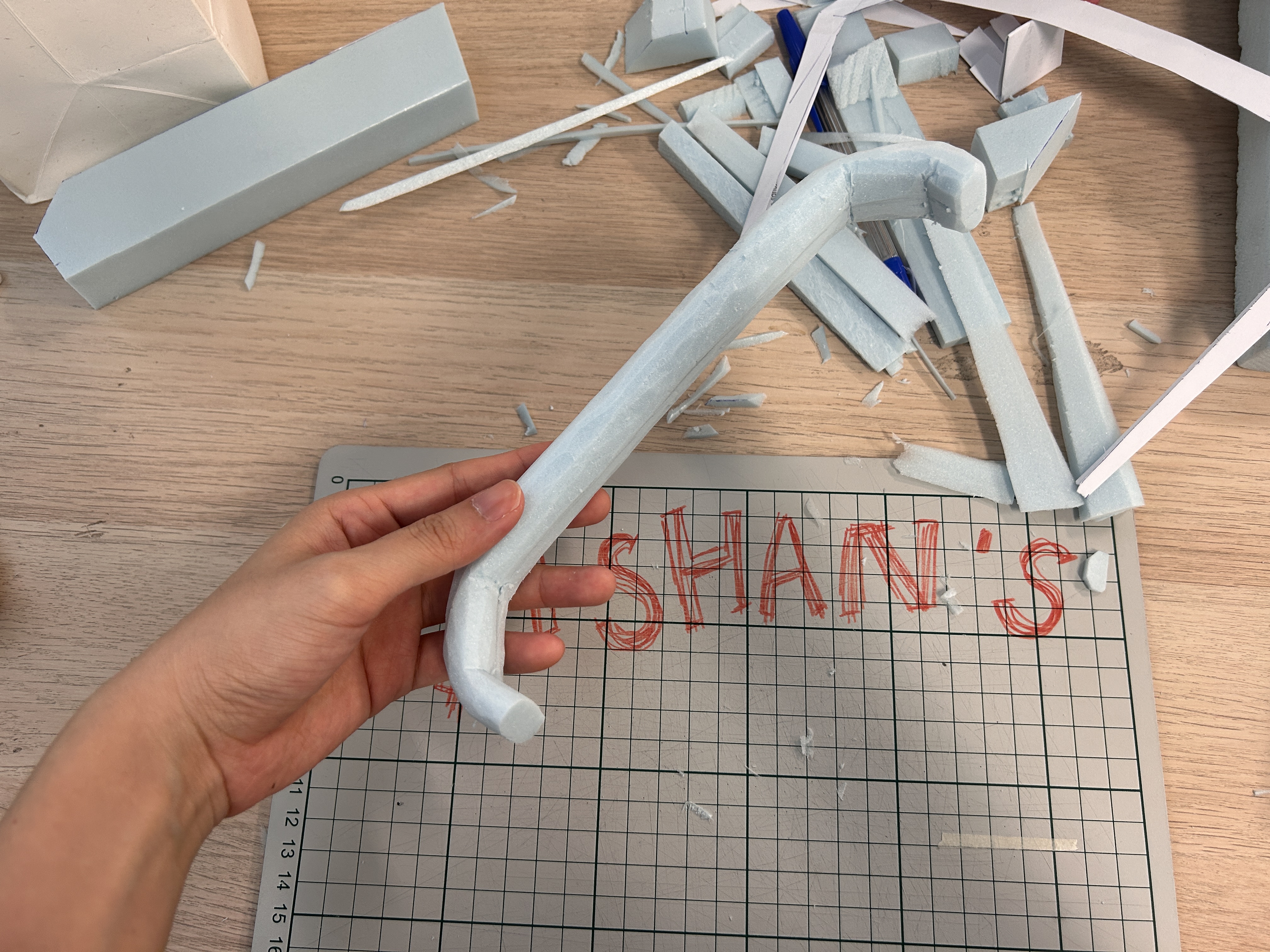

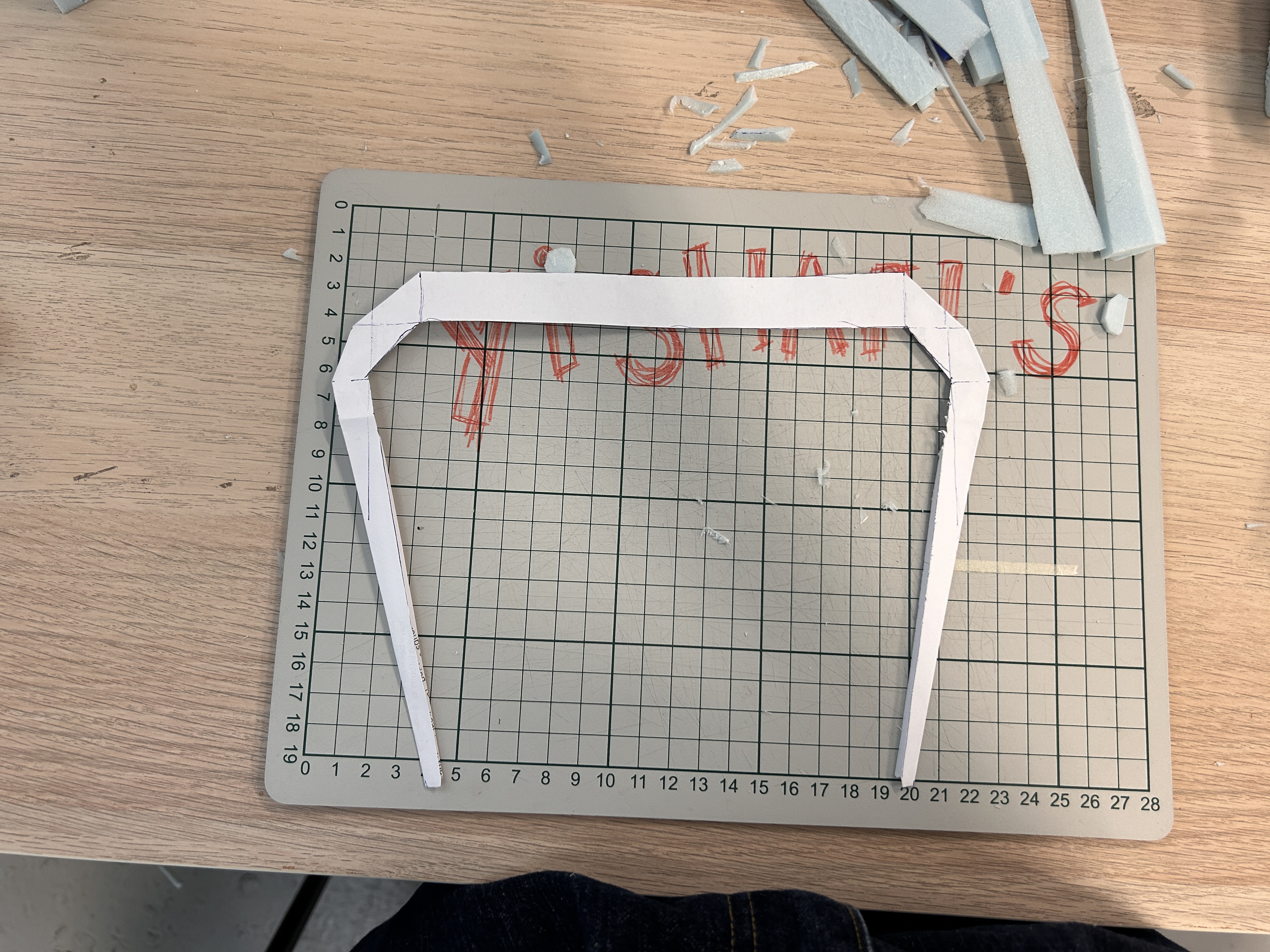

prototyping a basic structural form. y3s2w7. completed 19 february 2024.

base structure of the prototype.

when the sound sensor was attached on the wired prototype, it wouldn't hold up such that the sound sensor is posititioned at the mouth any more. i had to create and structure that would make use of other body parts to keep the sound sensor at where it should be.

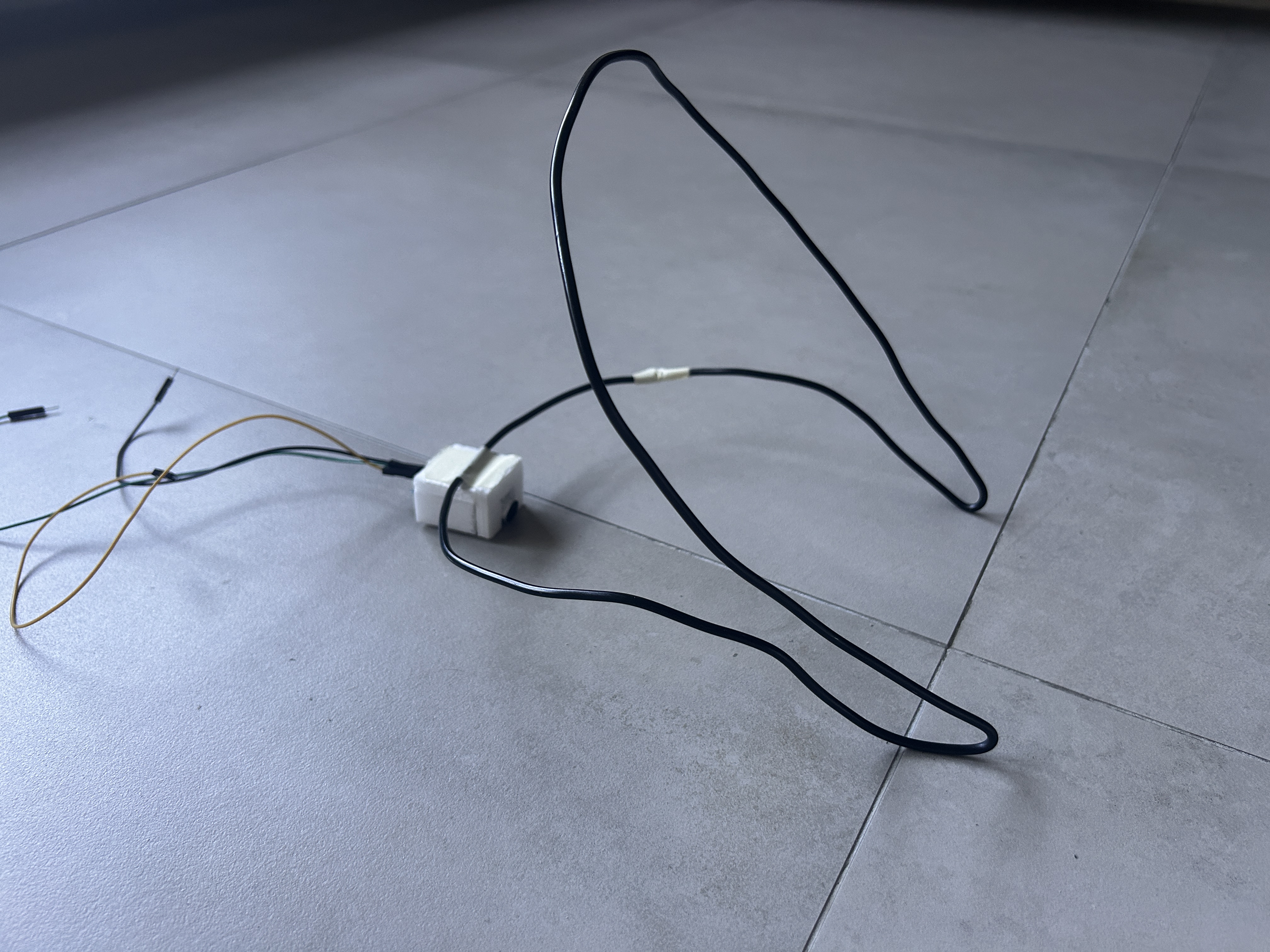

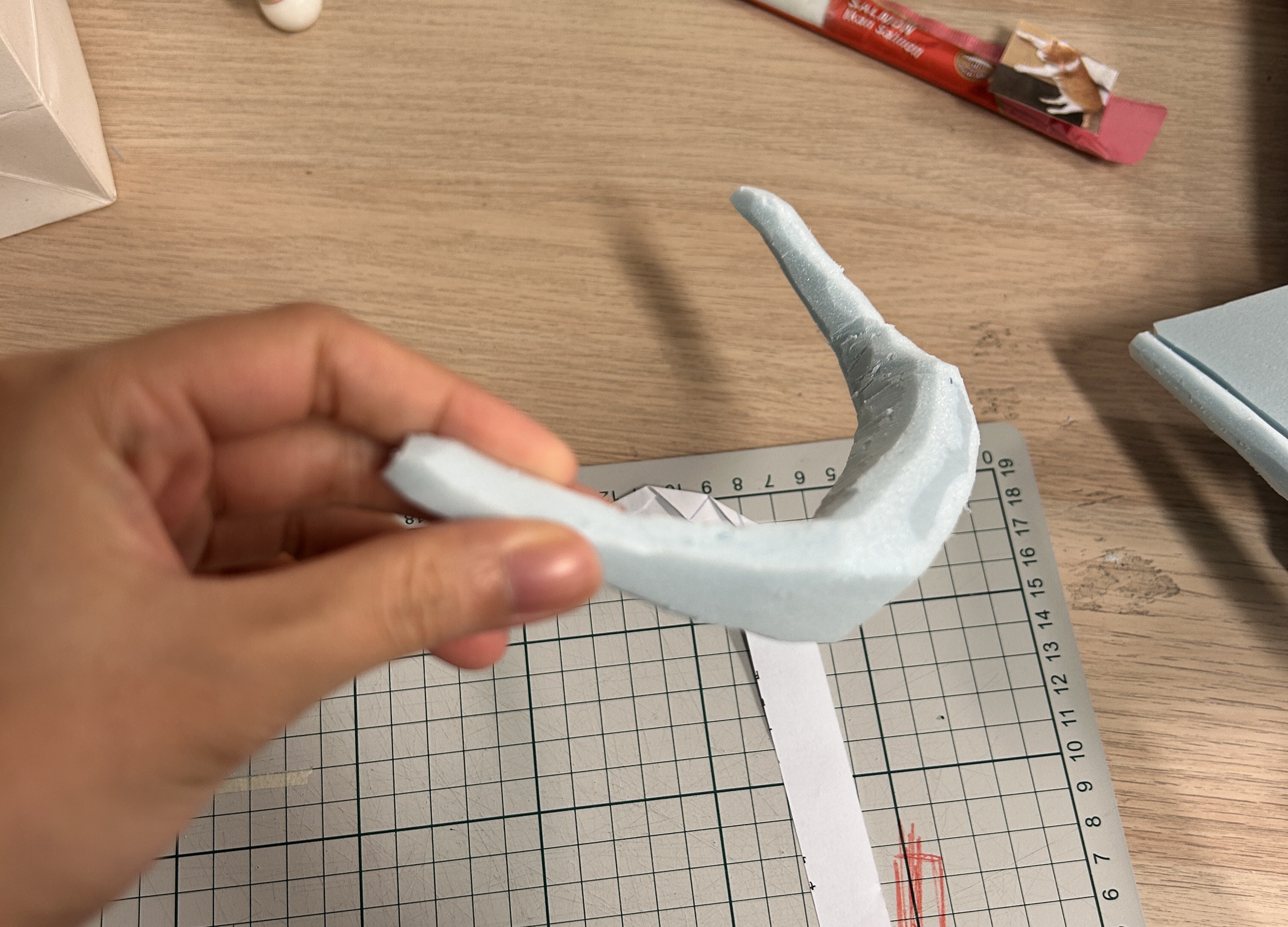

prototype-hopelessness 4.2: 3rd iteration of the prototype.

prototyping the basic structure. y3s2w7. completed 19 february 2024.

base structure with different forms and materials.

got my brother to help me test this out. the structure holds, but is very hard to put on. i realised this might be an issue with future iterations. the sound sensor might be in the right position, but the individual might not be able to put it on comfortably. this iteration is more comfortable to wear though, in comparison to the 1st and 2nd which relied on the prototype being hooked on the ears. this was also able to pick up sound better.

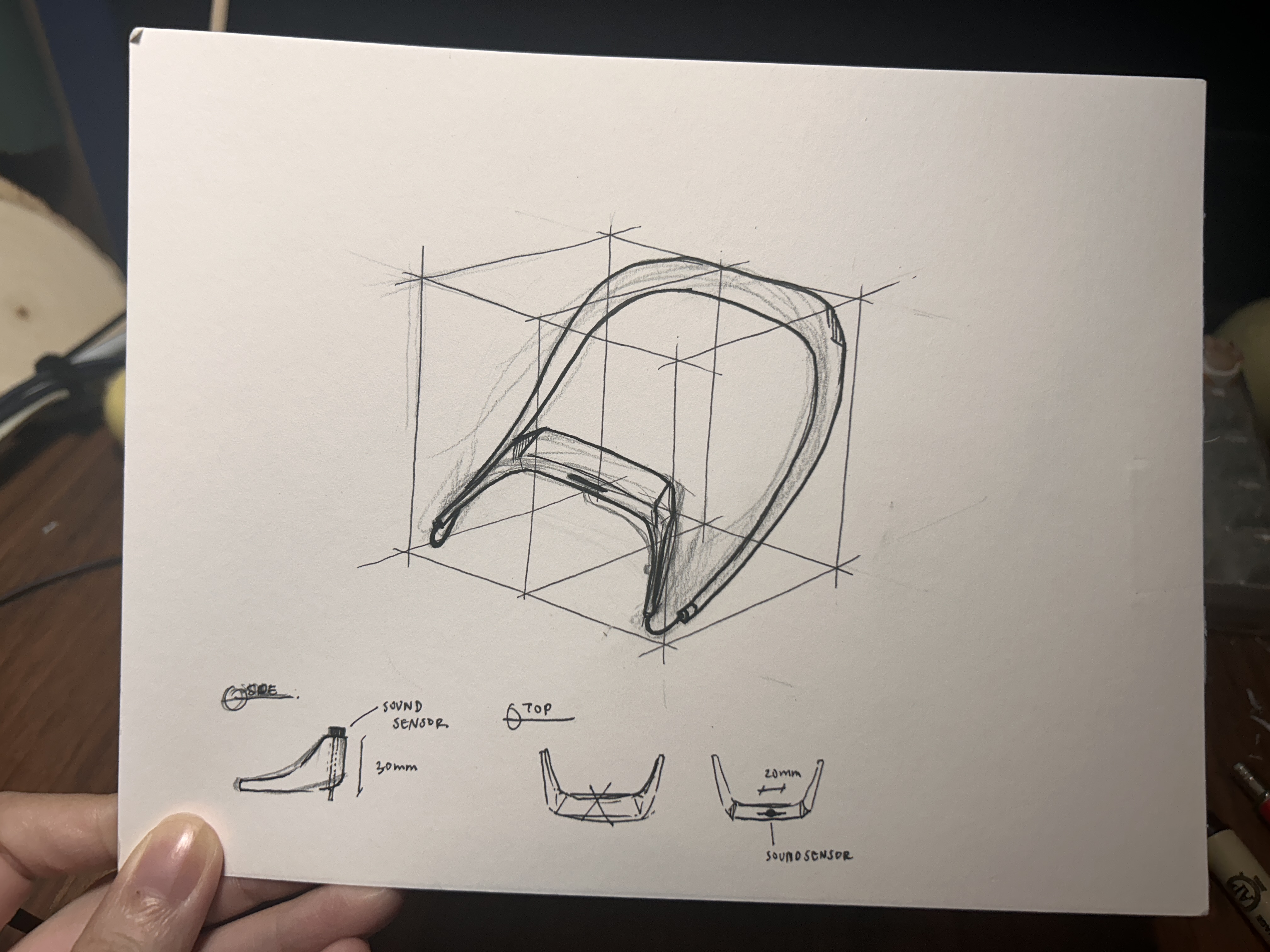

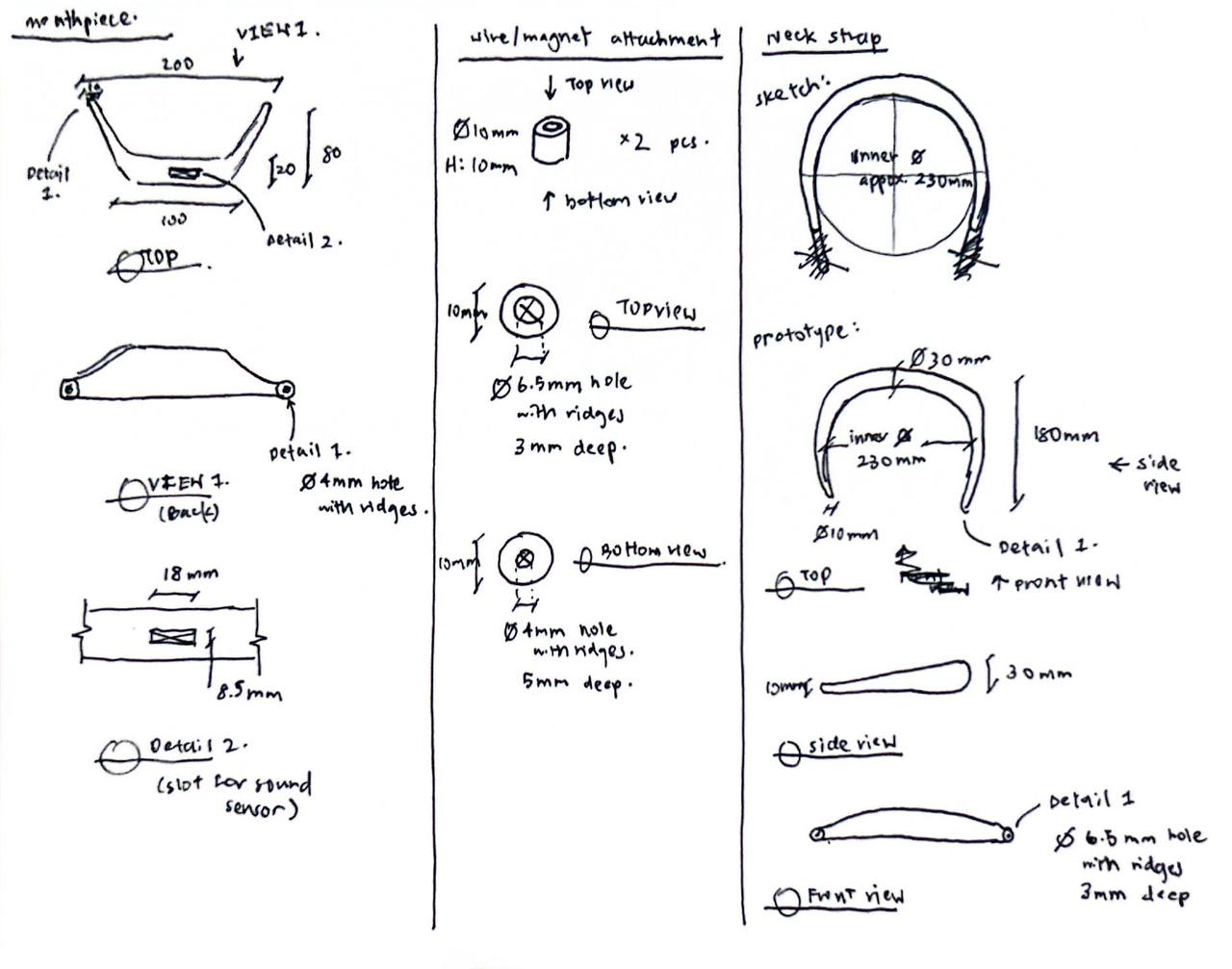

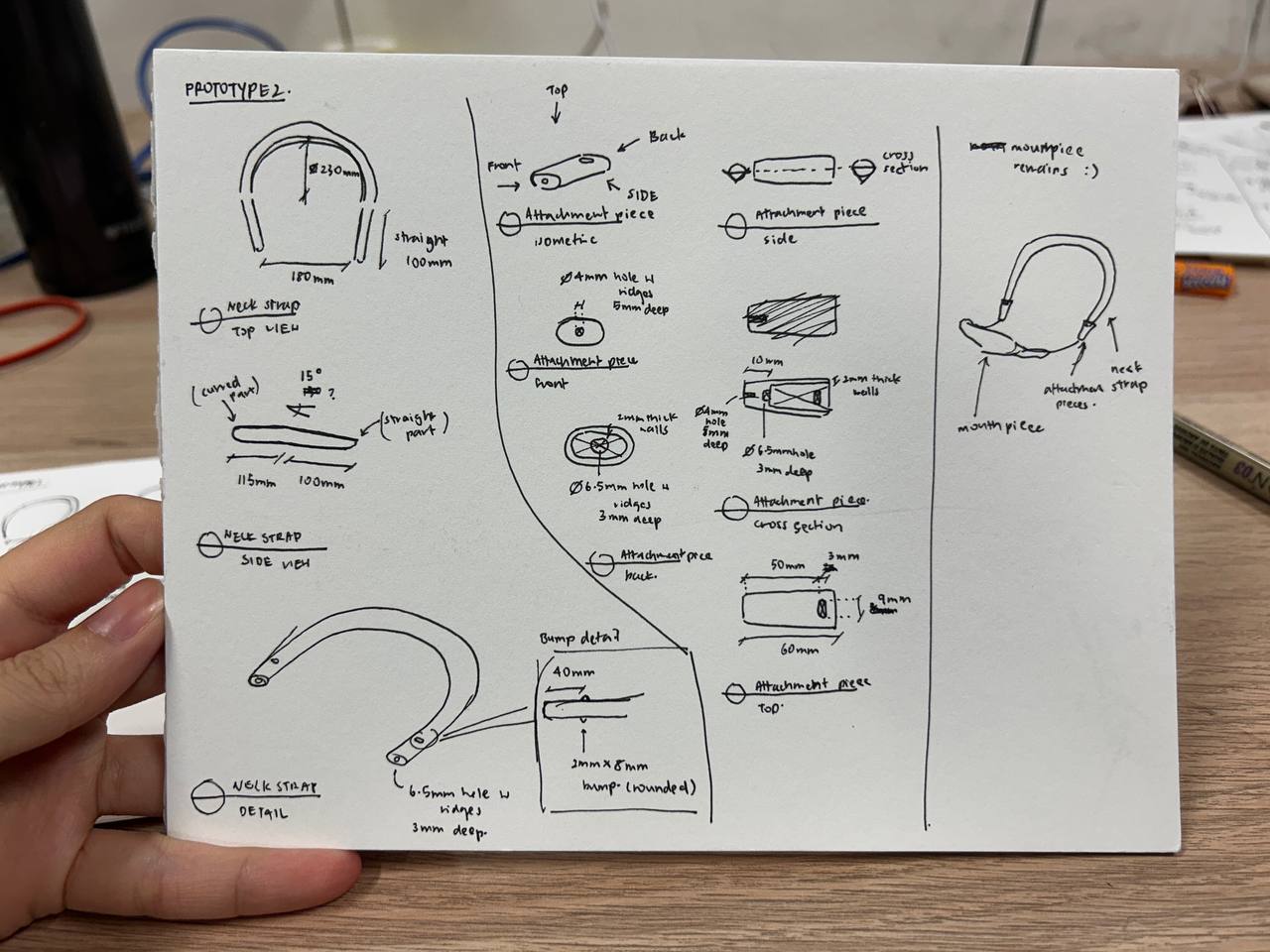

prototype-hopelessness 4.2: isometric sketch of the 4th iteration.

prototyping the structure. y3s2w10.

sketching out a proper structure.

i had a bit of trouble trying to envision out what the prototype should resemble. using both blue modelling foam and sketches, the structure of the prototype was slowly developed.

in order to solve the issue of the prototype being difficult to put on, i came up with the idea of making the mouthpiece area detachable. the area where it detaches could be connected with a bendable wire so it is adjustable as well.

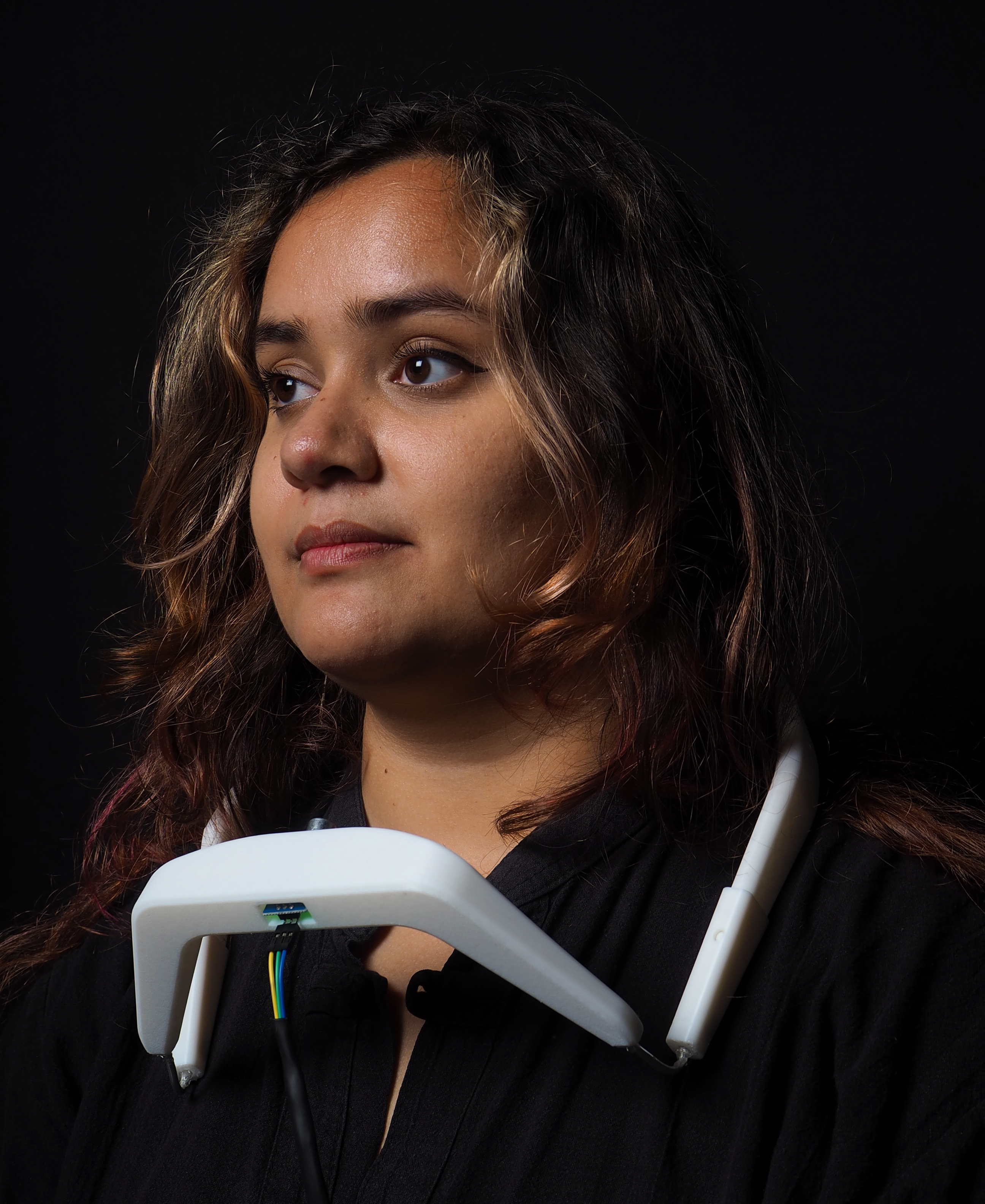

prototype-hopelessness 4.2: foam model of the 4th iteration.

prototyping the structure. y3s2w10.

blue foam model to be 3d printed.

i had a bit of trouble trying to envision out what the prototype should resemble. using both blue modelling foam and sketches, the structure of the prototype was slowly developed. the next step was to finalise the dimensions and send it out for printing.